The Rise of 3D Printing: Revolutionizing Manufacturing and Design

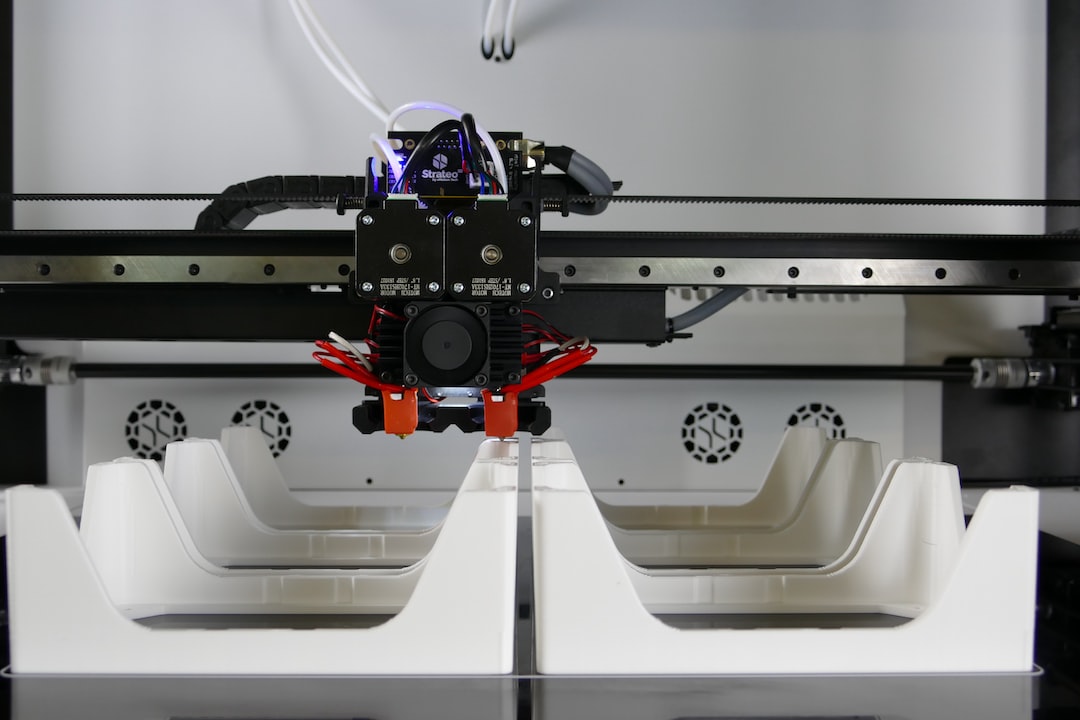

In recent years, the world has witnessed an incredible advancement in technology that is revolutionizing the manufacturing and design industries – the rise of 3D printing. Also known as additive manufacturing, 3D printing is the process of creating three-dimensional objects by layering materials, such as plastic, metal, or even human tissue, based on a digital design.

The impact of 3D printing on manufacturing is staggering. Traditional manufacturing methods require extensive tooling, lengthy production times, and large production runs. 3D printing eliminates many of these limitations by enabling the production of complex designs with minimal tooling and faster production times. This technology allows for the creation of intricate and customized products that were previously unimaginable. From aerospace components to medical implants, 3D printing is revolutionizing the way products are created.

One of the most significant advantages of 3D printing is its ability to reduce costs. With traditional manufacturing methods, creating customized or small-batch products can be economically unfeasible. However, 3D printing enables the production of unique and personalized items at a lower cost. This has opened up new opportunities for entrepreneurs and small businesses, allowing them to compete with larger manufacturers without the burden of high production costs.

Furthermore, 3D printing has the potential to reduce waste and lower the environmental impact of manufacturing. Traditional manufacturing methods often result in significant wastage of materials during the production process. In contrast, 3D printing only uses the necessary amount of material required for the design, minimizing waste. Additionally, the ability to create products on-demand reduces the need for excessive inventory and transportation, further reducing the carbon footprint.

Not only is 3D printing transforming manufacturing, but it is also revolutionizing the design industry. Designers now have the freedom to create complex and innovative structures that were previously limited by the constraints of traditional manufacturing methods. With 3D printing, architects can envision and construct intricate buildings and structures that are efficient, aesthetically pleasing, and environmentally sustainable. Moreover, designers can experiment with new materials and create unique textures and patterns that were once impossible to achieve.

The rise of 3D printing has also paved the way for breakthroughs in the medical field. Surgeons can now utilize 3D printing technology to create patient-specific implants and prosthetics that fit perfectly and enhance patient outcomes. This technology has also progressed the field of bioprinting, allowing scientists to print 3D human tissues and organs for research purposes and potentially in the future for transplantation.

In conclusion, the rise of 3D printing is revolutionizing manufacturing and design in unprecedented ways. From reducing costs to enabling customization and sustainability, this technology is reshaping industries across the globe. With continuous advancements and new possibilities on the horizon, it is clear that 3D printing is here to stay, transforming our visions into reality.